BC 312 UNDERWATER/THREADED HYDROPHONE

- hydrophone with a two-wired IEPE connection;

- screened and isolated from the environmental impact;

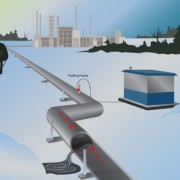

- monitoring and diagnostics of liquid pipeline systems;

- inspecting subsurface part of sonar structures.

POR (price on request)

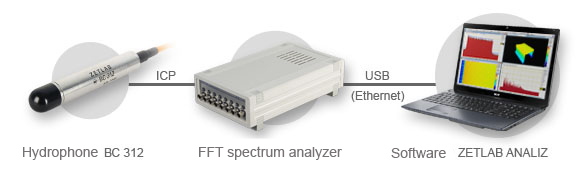

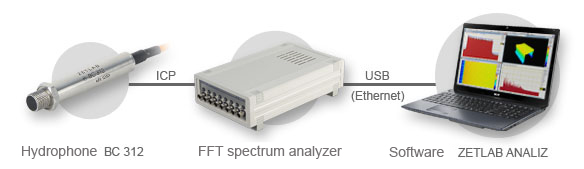

APPLICATION EXAMPLE

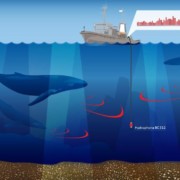

High-sensitivity multicomponent phased hydroacoustic systems for signal source detection and localization.

SPECIFICATIONS

of BC 312 underwater/threaded IEPE hydrophones

| SPECIFICATIONS | ||

|---|---|---|

| Designation | BC 312 | |

| Version | underwater | threaded |

| Nominal sensitivity | 200 µV/Pa | 150 µV/Pa |

| Sensitivity level (relative to 1V/µPa) | -192 dB | -194 dB |

| Frequency band | 20…20,000 Hz | |

| Self-noise*, RMS | 0.02 Pa | |

| Maximum value of measured sound pressure range | 50 kPa | |

| Limit static line pressure** | 60 MPa | |

| Output direct voltage level | 10…13 V | |

| Power | IEPE (DeltaTron/ ISOTRON) | |

| Supply voltage | +(18…30) V | |

| Supply current | 3 mA | |

| Explosion-proof version | — | upon request |

| Casing material | stainless steel | |

| Dimensions (length × casing diameter) | 173 × ⌀23 mm | 171 × ⌀23 mm |

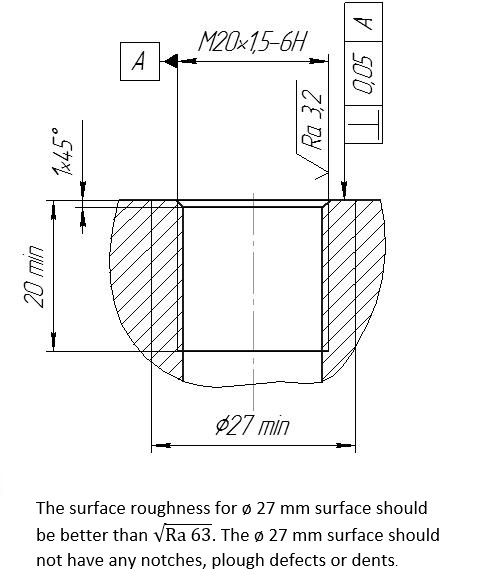

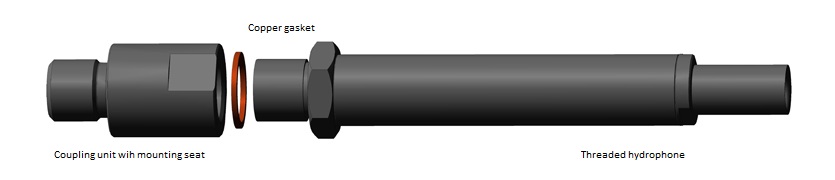

| Coupling thread | — | M20×1.5 |

| Weight (without cable) | ||

| Cable standard length | 10 m | 2 m |

| Maximum cable length | 100 m | |

| Cable outer diameter | 10,2 mm | |

| Cable type | coaxial, PVC coating, central wire, screened, resistive to the environment containing sulfuric acid | |

| Cable plug | BNC | |

| Measurements operation environment | water, air, oil and oil products, natural gas | |

| Operating environment temperature | 0…+60 °C | |

| Environment air temperature | −60…+80 °C | |

* Intrinsic noise at the input within the frequency range of 10 Hz from the frequency range upper limit.

**The limiting hydrostatic pressure is indicated for the receiving element of the hydrophone and can be limited by the technical characteristics of the cable, in the case of immersion studies.

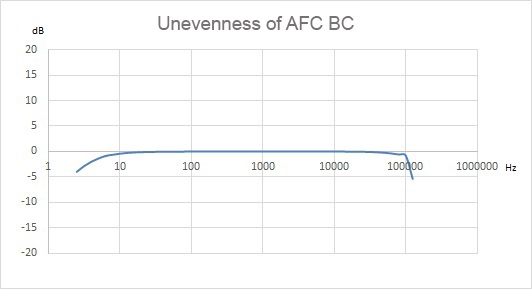

Hydrophones BC 312 are dynamic pressure transducers with even response curve throughout the whole range of frequencies observed in any homogeneous medium, including air, sea and fresh water.

Hydrophones BC 312 are used to determine explosion pressure in the range up to 1,000 kPa, pulse duration 2-5 ms (time sensitivity: some 0.1 ms).

Hydrophones BC 312 are used in hydroacoustics for reading-through underwater signals and noise, for measuring purposes, and also as components of beamed receiver hydroacoustic antennas.

Hydrophones BC 312 can be supplied without an integrated amplifier, in such case, it can be used as a sonar transmitter.