Vibration testing

Vibration testing can be described as an integral part of almost every industrial process. Imitation of environmental mechanical impact and operational environment (in particular, imitation of transportation vibration), contributes to the enhanced reliability, long-term operation and high functional qualities of the equipment under testing.

Taking into condsideration the importance of vibration testing performance, it seems reasonable to use a comprehensive approach to the selection of the system and the relevant testing modes.

In this section, you will find information concerning selection of the vibration testing systems, configuration of the shaker controllers parameters, implementation of tests for a particular vibration type, and common theoretical aspects relating to the vibration testing performance.

Main parameters of oscillation system and interrelation of vibration parameters.

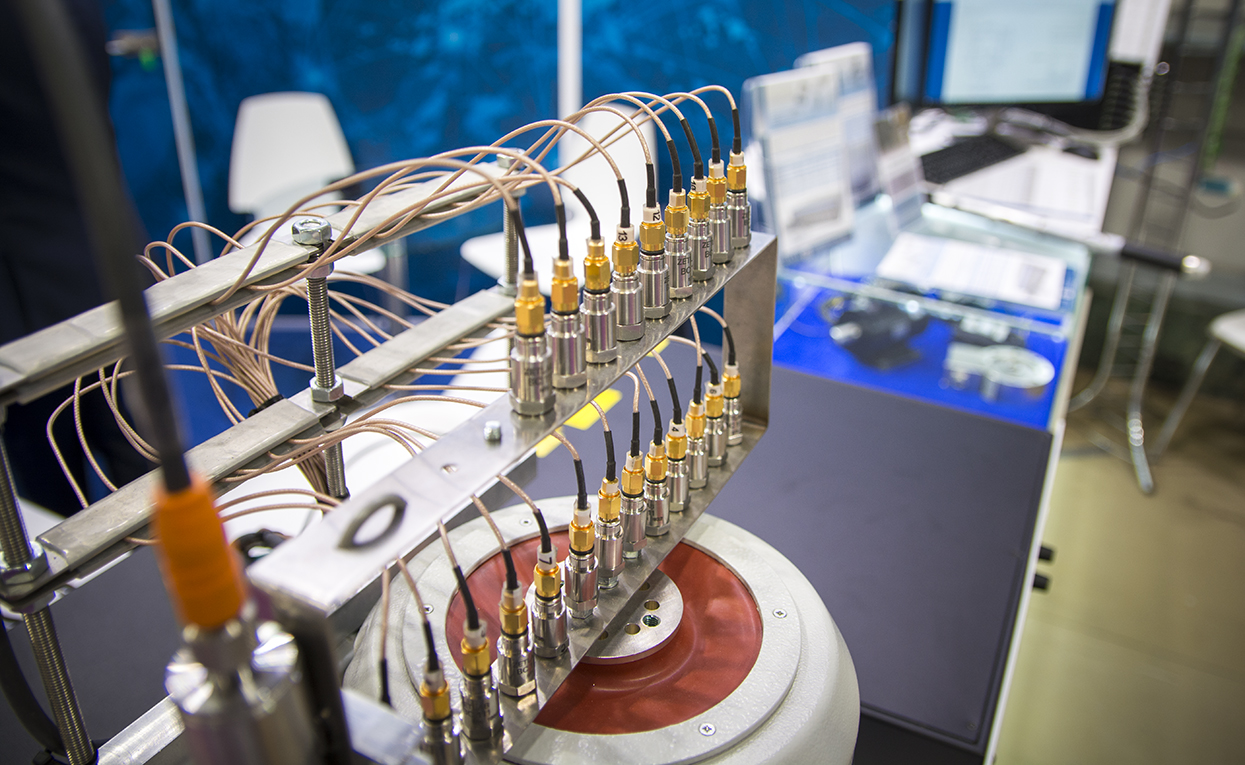

Operational functions of shaker controllers manufactured by ZETLAB Company

FAQ relating to the basic characteristics and specifications of the shaker controllers (VCS) by ZETLAB.

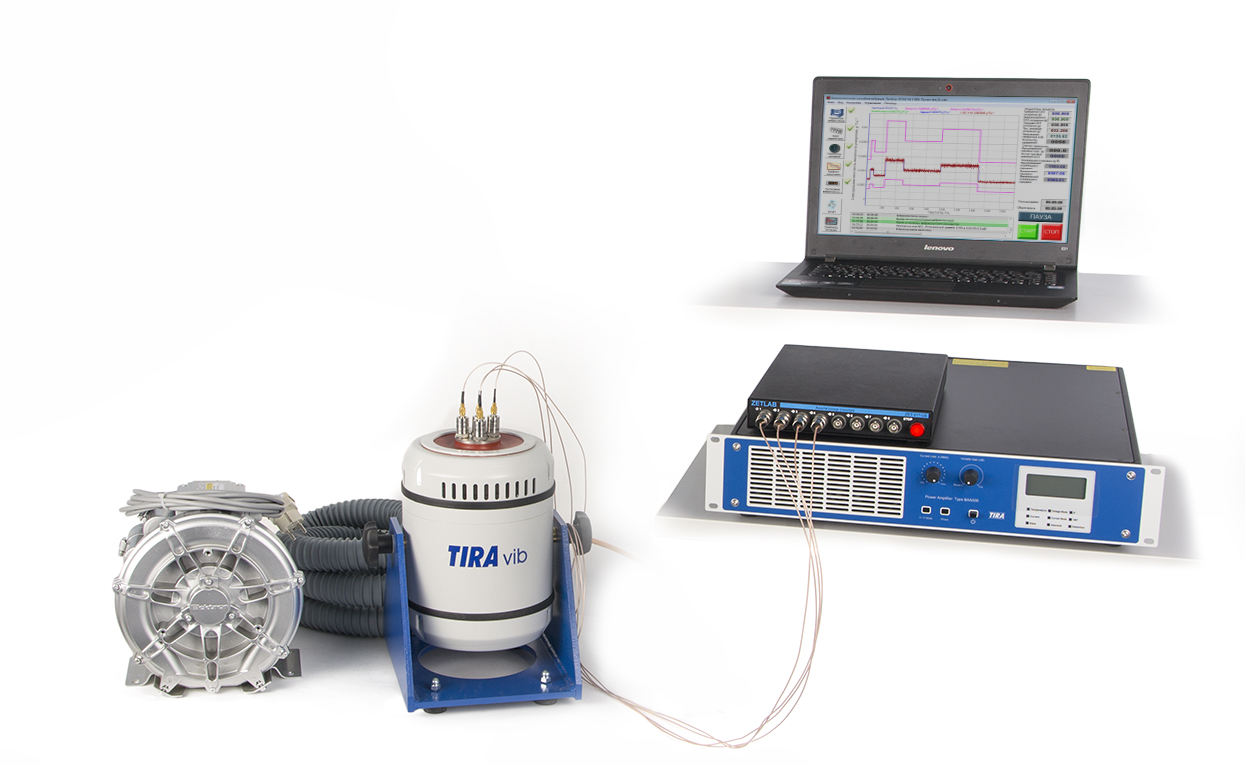

Selection and operation of the vibration testing system

The major parameters to be considered during selection of the vibration testing system, that would be able to produce the required mechanical oscillations in compliance with the purpose of the test.

Enumeration of possible defects, that are likely to occur in the course of system operation.

Practical implementation of the shaker controllers by ZETLAB Company for addressing the most common tasks.