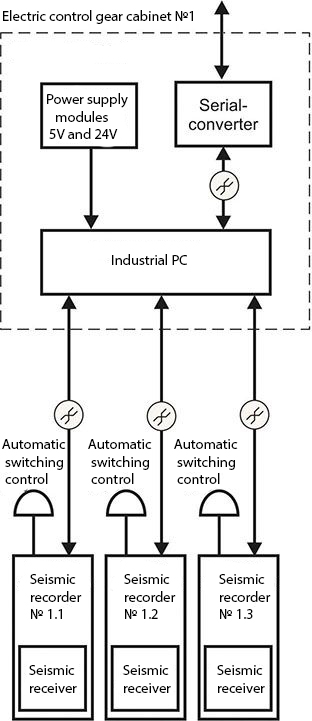

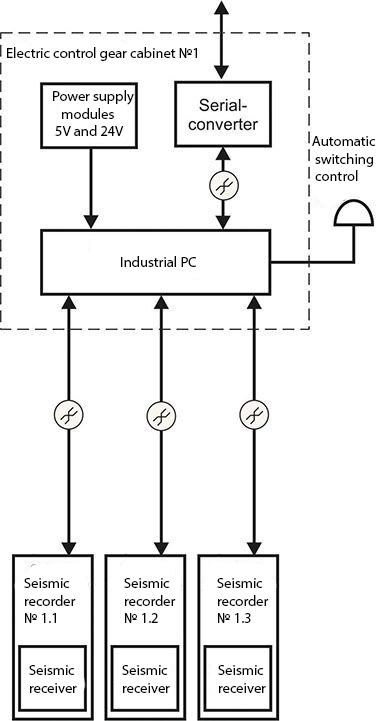

When observation points are established, there are normally at least two seismic receivers with sensitive velocimeter and a broadband acceleration meter. In the case, if a high operational security level is required, up to 6 acceleration meters can be installed.

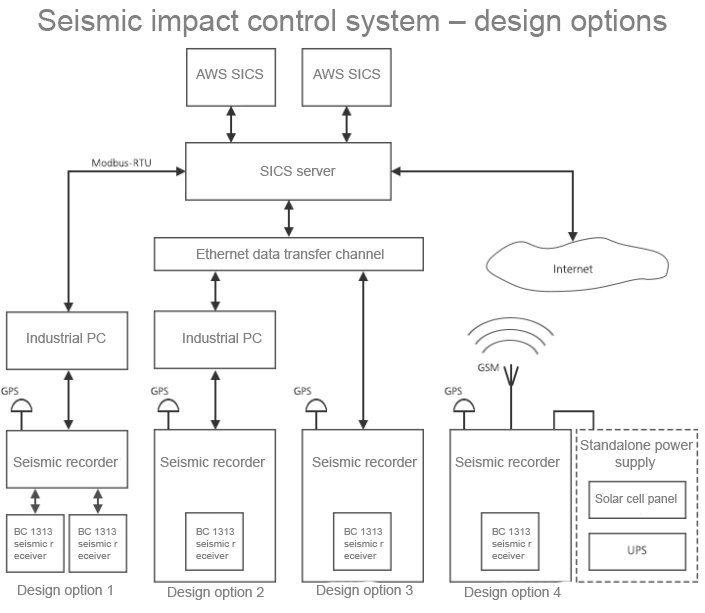

For the purpose of increasing the system reliability, one can install the industrial PC for preliminary data acquisition and processing. The processed data are more compact in volume if compared to the source data, hence, the data can be transferred via low-speed communication lines (IEC 60870-5-104, MODBUS RTU, dial-up modems, GSM/GPRS or as GSM/SMS notifications).

There are several schemes of seismic recorders synchronization:

individual— the seismic recorder is synchronized by integrated module and GPS antenna;

group — industrial PC or one of the seismic stations is synchronized by GPS, while the remaining stations are synchronized by PTP via internet.

In order to implement synchronization via PTP, there should be established a local network using copper or optical wire.