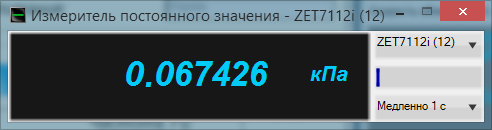

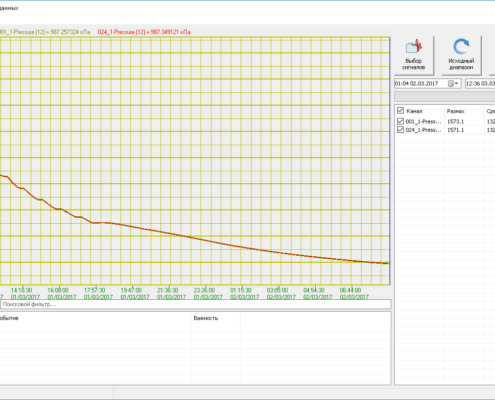

ZET 7112-I VER.2 digital gauge pressure

(open membrane)

- Integrated primary transducer

- Open membrane

- Ready for operation

- CAN 2.0 interface

POR (price on request)

Upper measurement range is to be specified in comments to the order.

* Minimum order value: from 7 700 USD

Specifications

of ZET 7112-I VER.2 digital gauge pressure (open membrane)

| Metrological specifications | |

|---|---|

| Measured value | overpressure |

| Upper limit of pressure measurement range | 0,1 MPa; 2,5 MPa; 6 MPa; 16 MPa; 25 MPa; 60 MPa |

| Resolution | 0.005% |

| Measurement error (from the measurement range) | 0,1 % |

| Additional measurement error (attributed to temperature change) | 0,1 %/10 °C |

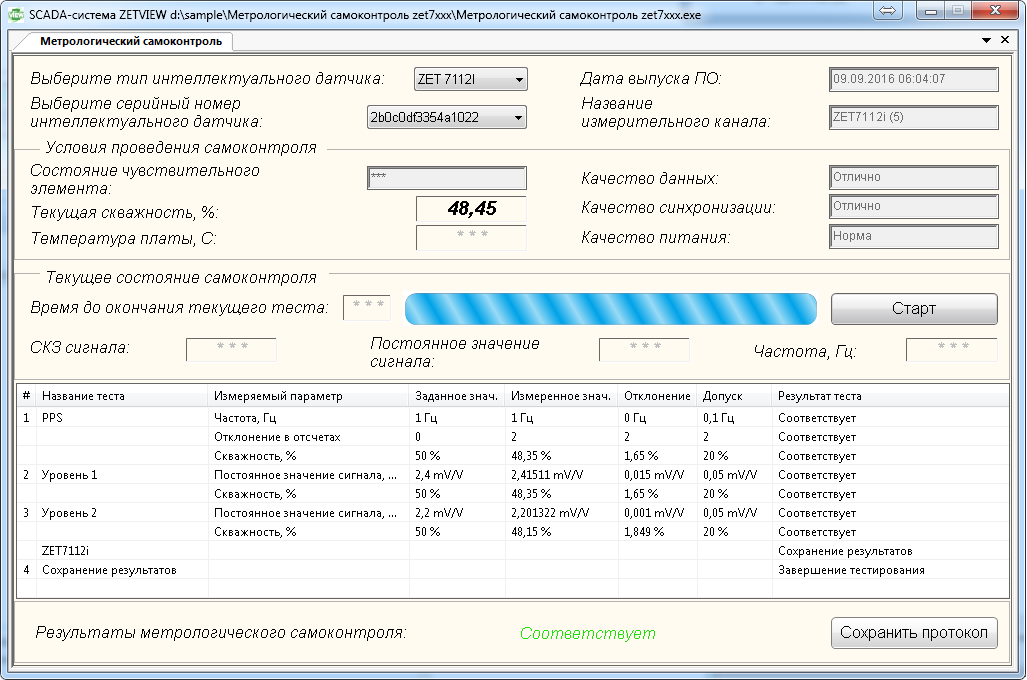

| Parameters diagnostics | power control, data quality control, sensing element integrity control |

| Technical specifications | |

| Data refresh rate | 1, 5, 25, 100, 200 Hz |

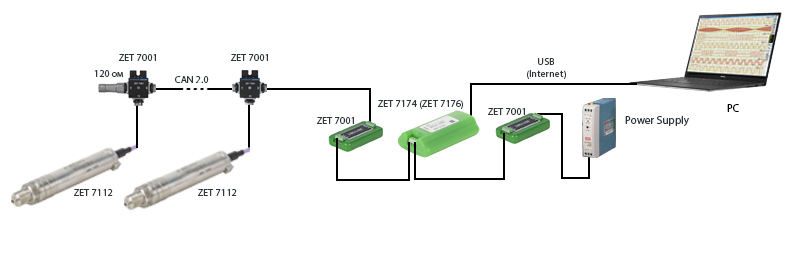

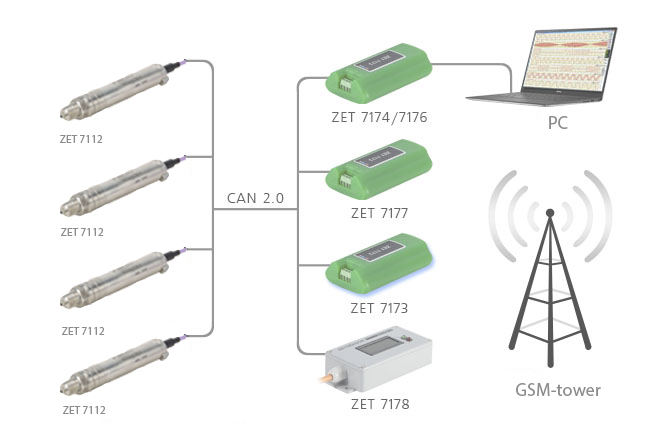

| Data transfer interface | CAN 2.0 |

| Exchange speed | 100, 300, 1000 kbps |

| Operational specifications | |

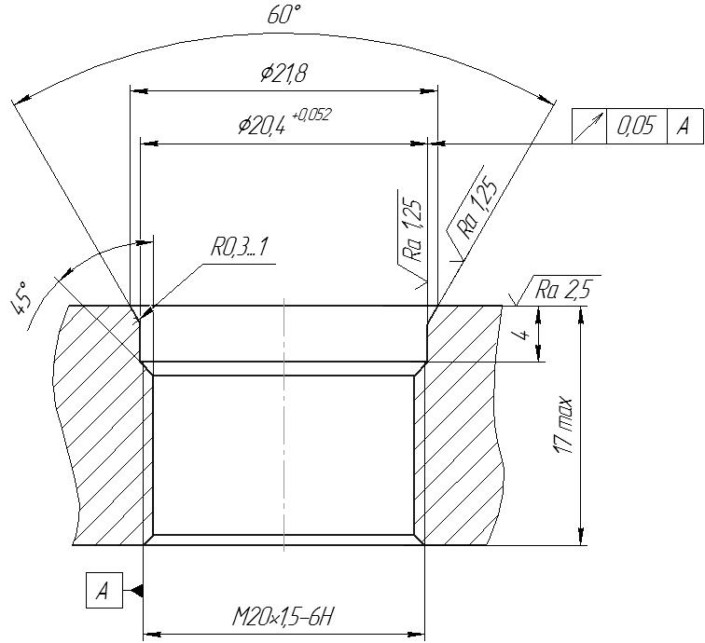

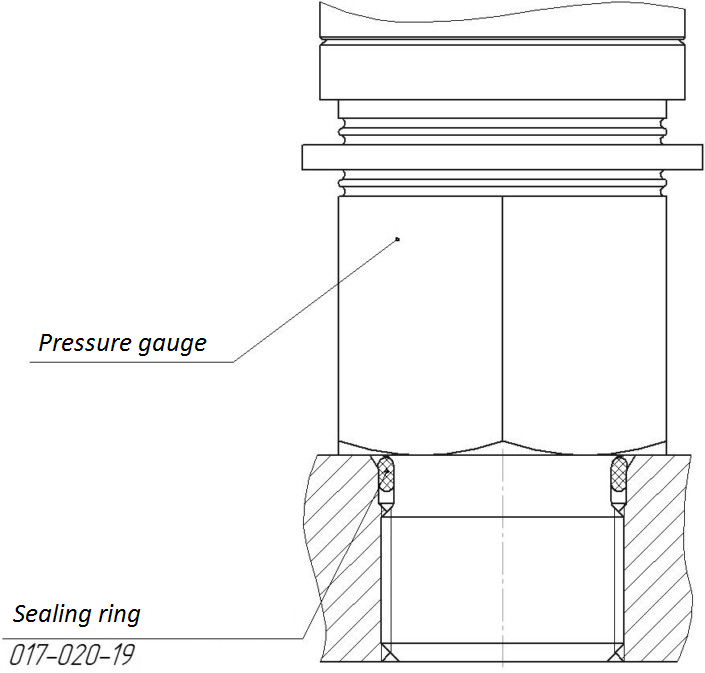

| Membrane type | open membrane |

| Dimensions | ∅34×190 mm |

| Weight | 380 g |

| Device power | from 9 to 24 V |

| Consumed power | 0,5 W |

| Reverse polarity protection | yes |

| Operational temperature range | from -40 to +100 °C |

| Operation environment | liquids and gases non-aggressive to titanium alloys and stainless steels |

| Design versions | Standard (IP63 protection degree) Explosion-proof* (explosion protection of 1ExdIIAT6X type, cable length – 4 m) |

| Pressure overload | 1,5×Upper limit of pressure measuring range |

| Electromagnetic compatibility EMC | |

| IEC 61000-4-2, ESD | contact 4 kV; air 8 kV |

| IEC 61000-4-4, EFT | power supply 0,5 kV; signal 0,25 kV |

| IEC 61000-4-5, Surge | 500 V |

* Price is calculated on individual basis