Temperature measurements using ZETSENSOR products

Temperature measurements are performed using thermocouple and a measuring module ZET 7020 TermoTC-485 or ZET 7120 TermoTC-CAN. Measurements results can be displayed on a digital indicator (offline measurements), be recorded together with temperature diagram (temperature recording), and be used in control systems (temperature adjustment). For control purposes one can use a solid-state relay having small response voltage value and a wide range of switching load.

Thermocouple of S,R type-2488/2 ХА |

Thermocouple of S,R type-0198/1 ХА |

Solid-state relay |

Solid-state relay |

Temperature recoder can be used for climatic chambers cerftification purposes. In this case the temperature transducers are placed in the corners and at the centroid of the climatic chamber. The Software “Multichannel recorder” is used for TC-s values control and temperature monitoring for each of the control points.

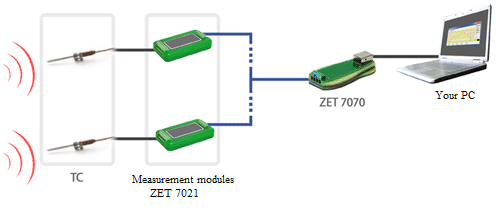

Multi-channel distributed temperature measurement system

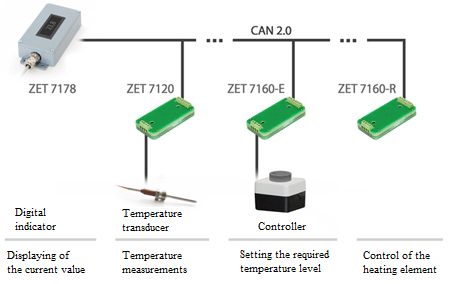

In the course of climatic tests performance ZETSENSOR devices serve as metering and control units (see the Figure “Off-line temperature controller diagram”):

- temperature measurements are performed by means of a thermocouple, the thermocouple’s signal is processed by ZET 7120 measuring module,

- current temperature value is displayed at the digital indicator (for operator’s control) and is also recorded to an off-line data storage or to a PC (in the case if it is necessary).

- the controller sets the temperature value be maintained, this value is transmitted to the measuring system by means of ZET 7160-E module,

- ZET 7160-R controls actuator in accordance with the preprogrammed algorithm using current thermal sensor values, thus providing the maintenance of the pre-set temperature level.

The system allows to control the speed of chamber’s heating and cooling, to maintain the set temperature, alarm activation and climatic chamber test process record keeping.

Off-line temperature control system diagram

Using intelligent sensors of ZETSENSOR series for temperature measurements is cost-effective if compared to using similar measuring controllers currently available on the market.

As a sensing element for temperature measurements applications one can also use thermoelectrical transducers (thermocouples) of the following types:

- R — (Platinum — 13 % Rhodium vs Platinum);

- S — (Platinum — 10 % Rhodium vs Platinum);

- B — (Platinum — 30 % Rhodium /Platinum— 6 % Rhodium );

- J — (Iron VS Copper/Nickel);

- Т — (Copper VS Copper/Nickel);

- Е — (Nickel-Chromium vs Copper/Nickel);

- К — (Chromel / Alumel);

- N — (Nicrosil/Nisil);

- А-1 — (Tungsten/Rhenium);

- L — (Chromel/Copel).

Primary transducer can be selected in the THERMOCOUPLES section.

Thermocouple operating principle is based on thermal EMF value change at the junction point of thermocouple’s elements. In this case no additional power supply source is required, since the output voltage is produced by thermoelectric properties of the thermocouple elements materials. Thermal EMF is formed between conductors having different chemical or physical properties.

Additional thermal EMF take place at the connection point between the thermocouple and the measuring system. This actually means that the system’s input receives a group of thermocouple signals as well as signals from the thermocouple itself. Nowadays in modern industry a “cold junction compensation method” is widely used. The point of this method is that the cold junction temperature at the thermocouple connection point is measured by a different temperature sensor (i.e. by the the cold junction compensator). Then the measured value is deducted from the operating thermocouple temperature value on a software or hardware level.

Measuring modules of ZETENSOR series have an integrated cold junction compensation.The measurements are performed depending on thermocouple type and cold junction compensator’s readings. Thus, at the output of the measuring unit there is formed a measured temperature value that does not require any further processing by the user.

The thermocouples have a wider measuring range (from −100°С up to +1800°С) if compared to resistance temperature detectors – however, the measuring precision is still the same.

Thermocouple signals normally have a range from microvolt to millivolt, that is why it is necessary to take additional measures to decrease noise and pickup level. This is normally achieved by screening and decreasing wires length. Thus, using intelligent pressure sensors provides high measurements precision (due to the fact that the measuring module is located in close vicinity to the primary transducer).

For connection of the thermocouples to a measuring module one can use a special cable with thermoelectrical compensation properties.