The Separation of micaceous raw stock on the vibroboard

with the altering amplitude of oscillation at the long side of the board

At this moment, the processes of the vibrational separation on a board that is in steady motion with the same amplitude of oscillation at every spot of the operating surface have been sufficiently studied from the theoretical and practical points of view. However, in practice at certain conditions the board can perform variable motion, in which the amplitude of oscillation will be alternating quantity at the long side of the board.

That effect can be observed, for instance, with use of centrifugal vibratory drive and screw-shaped resilient elements when the plane of the centrifugal force of vibrators does not pass through the operating device’s center of gravity [1]. At that, the quality of separation can be sufficiently reduced [2]. In the other hand, the assumptions are known that by means of the wobbling motion mode of the board under the certain operational parameters the efficiency and productivity of the vibroseparator can be improved. However, the regularity of the vibroseparational processes is practically unstudied. For the purposes of detection and analysis, experimental researches conducted at the laboratorial vibroseparator [3] were carried out.

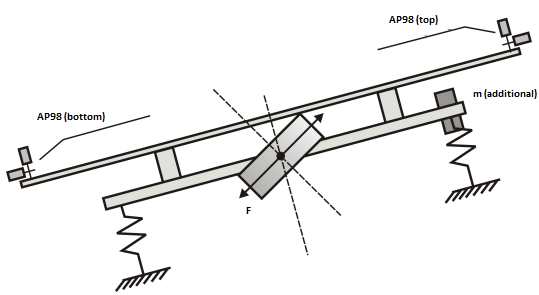

To define the law of the vibrodevice motion the set of the vibrometerical gear was used, such as: ZETLAB software, two-channel spectrum analyzer ZETLAB017-U2 and vibration inverters AP98 mounted pairwise, in normal and tangential direction (regarding to the operational surface of the board), in the upper and lower parts of the vibroboard (Figure 1).

Figure 1 — The layout of the board of the vibroseparator

The measuring vibrational parameters are normal and tangential (regarding to the operational surface of the board) projections of the board’s amplitude of oscillation at the upper and the lower part. The vibrational angle and the amplitude of oscillation were calculated on the basis of the given information:

A=√(AX^2+AY^2);

β=arctg(AX/AY)

The fine-sized micaceous raw stock of -20+0 mm type was used in the experiment, on which basis several artificial mixtures were prepared. These mixtures are easily separated into two fractions using vibroseparator. Conventionally, the small fraction with fineness of −1.0+0.2 or −1.0+0 was considered as a valuable component. The fraction compound of the large fractions was equal to −2.5+1.6 or −20+2.5.

The experiments were conducted in two different implementations. During the determination of the concentration process indicators, the sample of the material was fed to the vibrodevice with steady continuous flow to provide quality process of separation. By taking photo and video filming ingoing material was fed by small one at a time portions for more distinctive tracking of the fractions’ motion trajectories.

Four modes of the wobbling operation of the board were examined. At the one part of the board (in upper or lower one) the optimal amplitude of oscillation was provided (under the wobbling motion of the board and n=1,700 oscillations per minute for the examining raw stock it is A ≈ 6.0 mm [4]). At the other part of the board’s amplitude of oscillation were established above or below of the optimal value. The adjusted mode of the board wobbling motion was provided by means of the additional load weight alteration (Fig.1) and by the appropriate board unbalancing. The amplitude of oscillation of the board was changing by means of the vibrators’ centrifugal force adjustment.

Let us look at the results, obtained at different modes of the wobbling motion of the board. The total amplitude of oscillation in the lower part had near-optimal value (А=0.63 mm), in the upper part the amplitude is smaller (A=0.43 mm). At the same time the vibrational angle at the upper part of the board was β = 12°, and at the lower β = 53°.

At that mode, we can see infringement of the mineral raw stock separation process as the consequence of a small vertical acceleration in its upper part. The material is fed in the lower part of the board. During the process of vibroseparation the movement of the mineral raw stock in the upper part of the vibroaparatus almost stops (Fig. 2). Under the action of transversal inclination of the board the material slowly displaces to the right side of the board and goes to the side receiving cells. This mode should not be recommended to common use, because the material movement process in the upper part of the board goes by too slowly, thus aggregation of the ingoing material on the vibroboard under its continuous feed is inevitable.

Figure 2 — The process of the vibroseparation with the amplitude of oscillation Аup=0.43 mm, Аdown=0.63 mm

With intention to increase the amplitude of oscillation of the board along its full length (preserving its given variable motion) the centrifugal force of the vibrators was increased. As a result the total amplitude of oscillation in the upper part of vibrodevice was А = 0.67 mm (β = 14°), in the lower part is А = 0.97 mm (β = 56°). However, the vertical acceleration of the board in the upper part of vibrodevice remains insufficient. The fractions’ velocity in the upper part of the board decreases greatly, that is why the small fractions moving too slow towards the upper receiving cells (Fig. 3).

Figure 3 — The process of the vibroseparation with the amplitude of oscillation Аup=0.67 mm, Аdown=0.97 mm

Analysis of the obtained results and video footage indicate that with sufficient increase of the board’s amplitude of oscillation weaknesses of the previous mode are not completely eliminated, and it does not allow to recommend this mode for the common use. Although the more intense motion mode of the lower part leads to decreasing of the separation quality, as large fractions fall in the upper receiving cells, having clutter up the small fraction type.

The amplitude of oscillation of the upper part of the board exceeds the amplitude of oscillation of its lower part. The total amplitude of oscillation in the upper part of the vibrodevice is А = 0.95 mm (β = 44°), and the total amplitude of oscillation in the lower part is А = 0.60 mm (β = 23°). In this mode, we can see a wide hand fan motion of the mineral mixture fractions (Fig. 4). The large fraction falls in the lower receiving cells, and the small fraction, in consequence of greater vertical acceleration in the upper part of the board, acquires greater velocity and falls in the upper receiving cells.

Figure 4 — The process of the vibroseparation with the amplitude of oscillation Аup=0.95 mm, Аdown=0.60 mm

This mode is described by high quality and productivity of the vibroseparation process. The bits rapidly spread away from the point of the material feed, dispensing along the motion trajectories according to its fineness, and forms wide hand fan trajectories. As the bits moves upward at the board the velocity quickly increases. In that way, more intense mode of moving bits allows to increase productivity of the separator without quality loss.

The amplitude of oscillation in the upper board is A = 0.63 mm, and in the lower – A = 0.39 mm. Vertical acceleration in the lower part of the vibrodevice is sufficiently lower then free fall acceleration; therefore the infringement of the mineral mixture separation process is observed; and almost the whole mass of the mineral mixture (after its feed on the vibrodevice) is transferred to the lower receiving cells. By summarizing the results of the experiment, we can make the following conclusions. The research of the board wobbling motion at certain conditions allows to increase productivity of the separator and quality of the separation. Decreasing the board amplitude of oscillation doesn`t give the positive results. For common use we can recommend the version of the board wobbling motion, in which the amplitude of oscillation of the upper part of the board higher than its lower part.

At the same time, the motion mode of the board’s lower part should correspond for the optimal mode that was set up in case of steady motion of the board. The amplitude of oscillation of the upper part of the board increases for 40-60% by means of displacing the gravity center of the separator’s moving part higher then working line of the vibrators centrifugal force. With regard to the micaceous raw stock, the total amplitude of oscillation in the upper part of the vibrodevice was A = 0.95 mm.

(AX= 0.68 mm, AY= 0.66 mm, β= 44°),

and the total amplitude of oscillation in the lower part of the vibrodevice was A=0,95 mm

(AX= 0.55 mm, AY= 0.23 mm, β= 23°),

Since with infringement of balance not only the amplitude of oscillation of the board but also the vibrational inclination is changed, it was decided to conduct an additional experimental research for clarification of the actual low of the vibroboard motion. The motion low with use of centrifugal vibratory drive, under condition of the board’s steady motion, straightline directed oscillations

The oscillograms of vibrodisplacement of the board in its upper and lower parts are shown in Figures 5, 6.

Figure 5 — The oscillogram of vibrodisplacement in the upper part of the board with tangential and regular direction

Figure 6 — The oscillogram of vibrodisplacement in the lower part of the board with tangential and regular direction

For visual reference, the diagrams of the board motion within axis AX – AY (Fig. 7, 8) with the help of the obtained oscillograms were drawn up. These diagrams show that the low of vibroboard motion almost coincide with straightline directed motion.

Figure 7 — The board motion trajectory in the lower part

Figure 8 — The board motion trajectory in the upper part

Thus, we can observe the following board motion regularity, which were received in the experimental way [1]. If the vertical projection of the amplitude of oscillation in the upper part of the board sufficiently exceeds the amplitude of oscillation in the lower part, than the center of gravity of the moveable part of the vibroseparator displaced upward regarding to operational flat area constrained force of the vibrators. By increasing the additional load weight, installed under the operational flat area of the vibrators’ centrifugal force, the vertical projection of the operational device’s amplitude of oscillation compensates at the long side of the board. The total amplitude of oscillation and vibrational angle can be changed in the similar way. The tangential projection of amplitude of oscillation almost doesn’t change in the upper and lower parts of the board.

Authors:

V.L. Lapshyn

N.V. Telnov