Accelerometer Verification

Verification of vibration measuring transducers requires the following:

- Visual inspection.

2. Checking electric insulation resistance.

3. Testing.

4. Checking electric capacitance.

5. Checking internal resistance.

6. Defining valid conversion coefficient.

7. Defining relative transverse conversion coefficient.

8. Defining bandpass flatness (АFR).

9. Defining amplitude nonlinearity (АR).

10. Defining setup resonance frequency.

11. Defining transverse resonance frequency.

This article describes automation of sensor verification process with vibration transducers basic parameters as an example:

- Defining valid conversion coefficient

- Defining bandpass flatness (АFR)

- Defining amplitude nonlinearity (АR)

Equipment Used for Verification

For verification of vibration transducers, the following equipment is required:

- Electrodynamic vibration board with power amplifier for vibration reproduction with preset parameters;

2. Standard vibration transducer for defining vibration parameters;

3. Coordinating amplifiers for connecting vibration transducers without integrated amplifier;

4. Generator for vibration board control;

5. Two voltmeters for registration of vibration sensors indications.

When choosing the equipment, take into account that reference vibration converter, coordinating amplifiers, voltmeters and generator must be registered in the measuring instruments register.

Verification Pattern

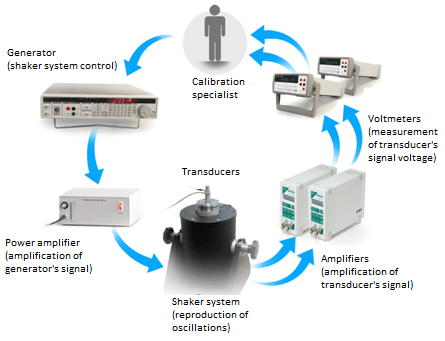

When defining basic parameters of vibration measuring transducers, a verification pattern is used as shown on the figure:

General verification pattern

Reference vibration transducers and vibration transducers for verification are installed on the vibration table and connected to electronic voltmeters directly or through an amplifier. A sinusoidal signal generator is used for vibration board control and connected to the vibration board through a power amplifier.

Actions of verification operator (one measurement):

- Adjusting generator signal frequency.

2. Setting voltage for a generator providing preset vibration level:

— adjusting an arbitrary voltage value,

— defining vibration level based on the signal amplitude transmitted by the reference sensor,

— increase of generator voltage if vibration acceleration amplitude is below the required level, reduction if vibration acceleration amplitude exceeds the required level.

3. Recording the voltmeter indications.

During measurements in the frequency range, constant vibration acceleration amplitude at different frequencies is reproduced. During measurements in the amplitude range, constant frequency with different values of vibration acceleration amplitude is reproduced.

Time-consuming results processing is required after all necessary measurements.

Thus, verification of a single vibration transducer may take 2 to 3 hours. An automated vibration sensor calibration system designed by our company reduces verification time to several minutes!