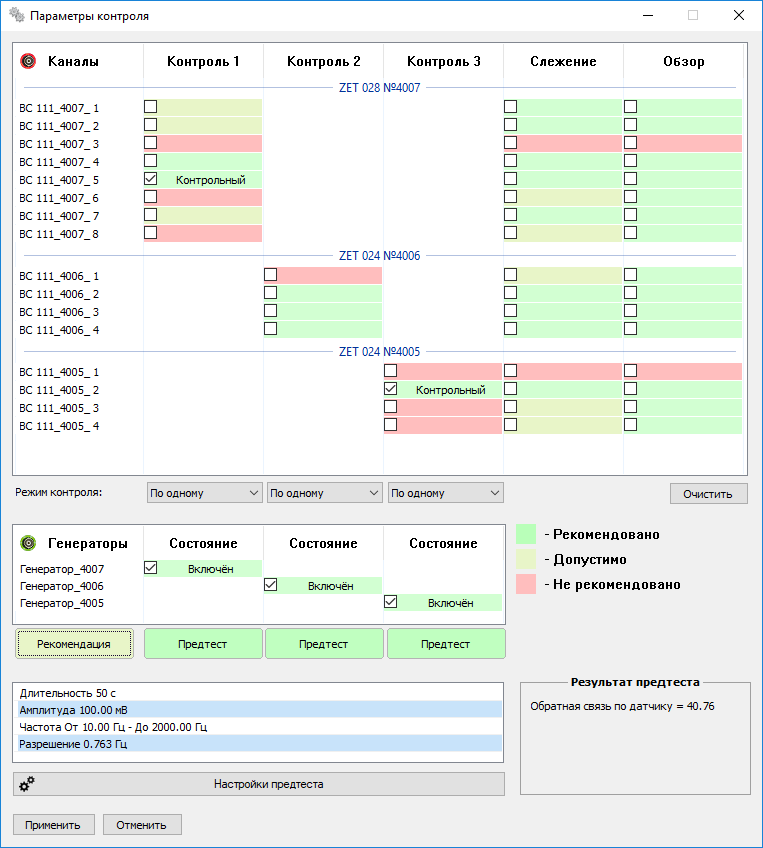

Control parameters

Pre-test of the system for the purpose of evaluating the optimal parameters to be used for test performance

Preparation for vibration testing is an important and labor-consuming process. It is attributed to the fact, that correct mounting of the transducers on the test specimen and selection of the reference transducer are crucial factors for the successful performance of the testing procedure.

The primary transducers (accelerometers) are mounted on the specimen in accordance with the applicable testing procedure. Then the transducers are connected to the measurement channels of the VCS. The software suite allows to assign a particular task (control, tracking, observation) for each measurement channel of the VCS.

The “Control parameters” program enables automated selection of the measurement channels to be used for particular tasks. The program sends a broad-band low-intensity test signal to the shaker system, while the shaker system is applying a certain impact to the specimen with the transducers attached to it. The software conducts analysis of the measurement channels response (i.e., the response of the transducers) for the compliance with the selected type of tests impact and produces recommendations concerning the use of each particular transducer.

The “Control parameters” program can be started from the main panel of the VCS software.

In order to conduct the pre-test of the system, it is necessary to select the channel to be used for test impact and to activate it. The software suite ZETLAB VIBRO allows to conduct vibration testing with up to 4 independent control channels.

Note

In order to conduct vibration testing with several independent control channels, it is necessary to have the corresponding number of VCS and shaker systems. In this case, in the “Control parameters” program one should select the generators to be used for vibration testing, and to conduct a pre-test for each of the control channels.

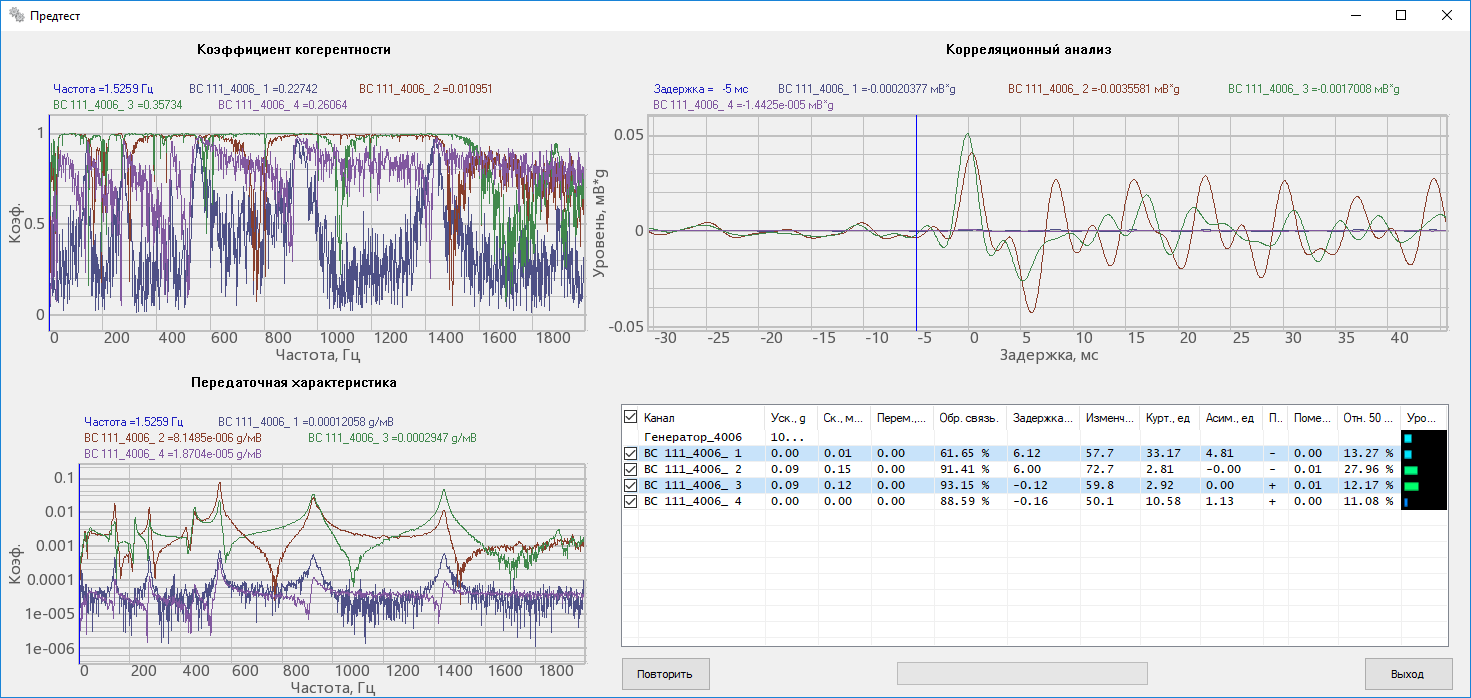

As the required parameters are set, click the “Pre-test” key of the “Control parameters” program. The program will initiate the process of analyzing the response of the measurement transducers to the applied impact.

The results of data processing will be displayed in the table at the bottom right section of the “Pre-test” program interface.

Upon completion of the pre-test process, click the “Exit” key. The “Control parameters” program will indicate the list of the channels with corresponding indication and recommendations in terms of testing performance based on the results of the pre-test. The color indication is as follows: green – recommended, yellow – acceptable, red – not recommended.

In addition to that, the “Pre-test” program also allows to detect a number of possible errors as well as to provide recommendations in terms of trouble-shooting. To activate this function, click the “Recommendations” key upon completion of the pre-test procedure. Below you can see a brief list of the most common system errors:

- high noise level

- insulation problems

- cable rupture or defect of the transducer

- wrong value of the transducer’s sensitivity

- insufficient contact

- low signal level

- high signal level

- triboelectric effect

- defect of the power amplifier

- disconnected ICP

- high value of signal’s DC component.

Supported hardware

The “Control parameters” program is included into the scope of ZETLAB VIBRO software suite (the software is supplied together with shaker controllers).