Tachometer

Tachometer is used for measuring the rotation frequency of shafts in machines and mechanisms, as well as for calculating the number of complete revolutions. Typically, for measuring the rotation frequency, optical or induction rpm sensors are used.

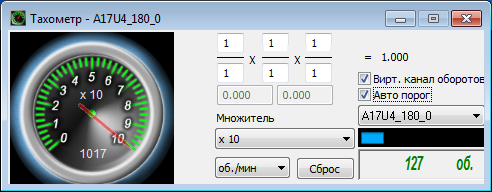

The indicator displays the rotation rate (rpm) and number of revolutions, whose values are taken into account from the program start.

For complex units such as gear boxes, a gear ratio is set. Optionally, it is possible to set thresholds for the actuation levels of the rpm sensor, both manually and automatically.

The tachometer signal parameters are valuable for diagnostics purposes, as well as for practical study of internal combustion engines (ICE) and other rotary mechanisms (turbines, compressors, pumps, fans, etc) characteristics.

Order Analysis is used for studying, troubleshooting, and balancing various rotating mechanisms.

For studying and troubleshooting the non-stationary processes during rotation, Angular Displacement Indicator is used.

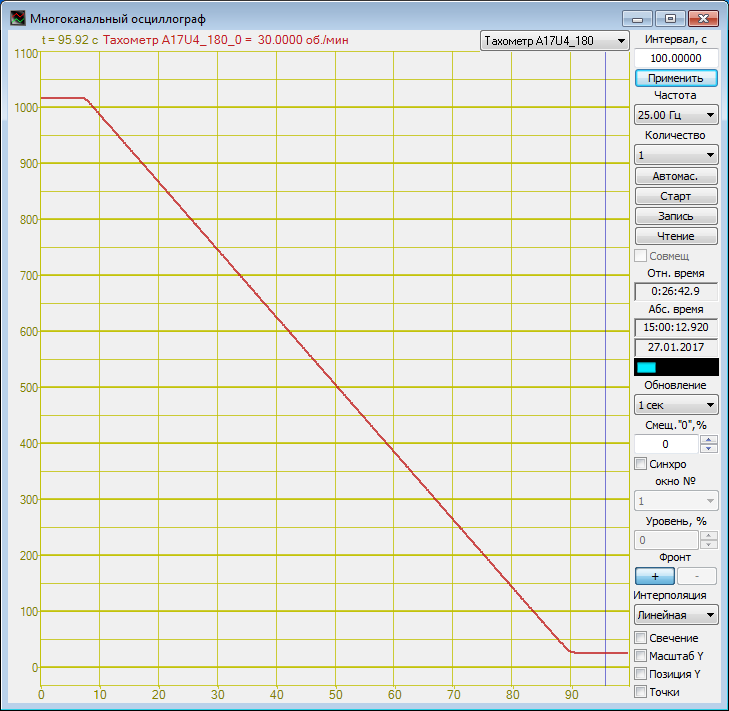

When using Multichannel Recorder, it is possible to obtain the number of revolutions per minute in the frequency display mode (frequency * 60 = rpm). Based on the obtained diagram parameters, the ACC/DEC processing time of ICE-s is determined. Based on these parameters, it is also possible to determine the system damping for further analysis. When the mechanism has a constant rotation frequency, using this diagram, one can analyze:

- behavior of the system rpm governor (restoration of the set rpm) in case of connection or change of the power consumer’s load;

- rotation non-uniformity degree under a constant load (especially for ICEs).

By integrating the instantaneous rotational speed values, it is possible to obtain the shaft torsional oscillations values in radians or degrees.

The measurement of the instantaneous speed difference (in two shaft sections) allows to determine the shaft twist angle (constant or variable) and to calculate parameters such as voltage in the shaft and the mechanism power.

The program “Tachometer” used together with “Multichannel oscillograph” program enables analysis of rotation frequency dependence on time parameter.

The figures below show an example of treadmill rotation speed register. Using this program one can estimate the time required for stand still as well as to analyze the engine perfomance after driving force shut-down.

Supported Hardware

Input data for Tachometer includes digital data of the ZETLAB server channel.

Tachometer is included into the following software packages:

- ZETLAB ANALIZ – FFT spectrum analyzer software;

- ZETLAB VIBRO – vibration controller software;

- ZETLAB TENZO – strain-gauge station software;

- ZETLAB SEISMO – seismic station software;

- ZETLAB NOISE – vibration meter-noise meter software.

Tachometer is included in the Measurement software group.