Digital strain gauge sensor ZET 7111

- Digital strain transducer ZET 7111

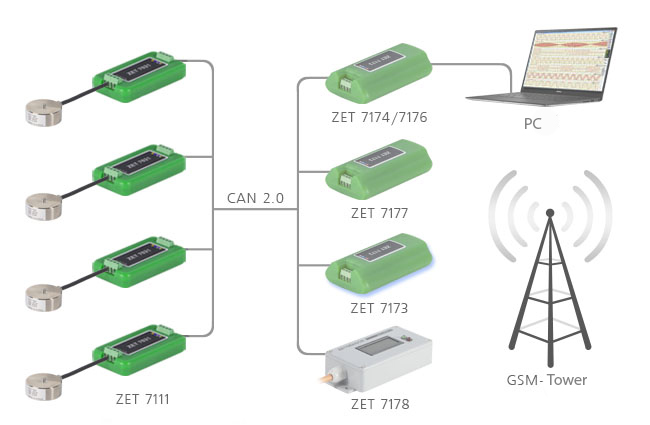

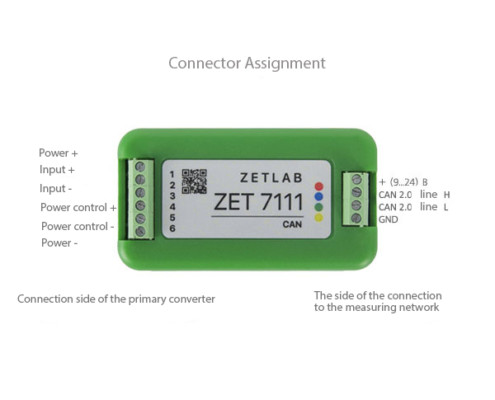

- Digital output CAN 2.0.

- Dynamic measurements.

POR (price on request)

Specifications

of the ZET 7111 Digital Strain Gauges

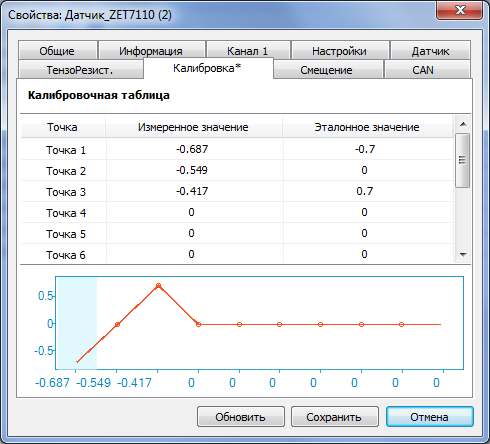

| Metrological Data | |

|---|---|

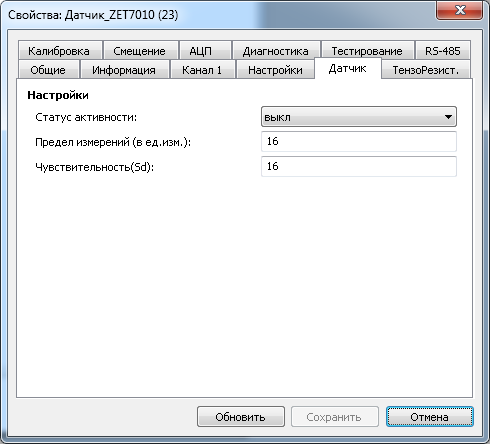

| Measured value | deformation, strain, torque, force |

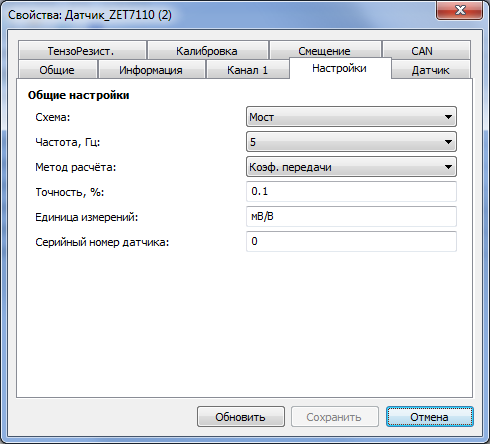

| PT electric voltage measuring range | -7 to +7 mV/V |

| Common-mode voltage range | 0 to 4,5 V |

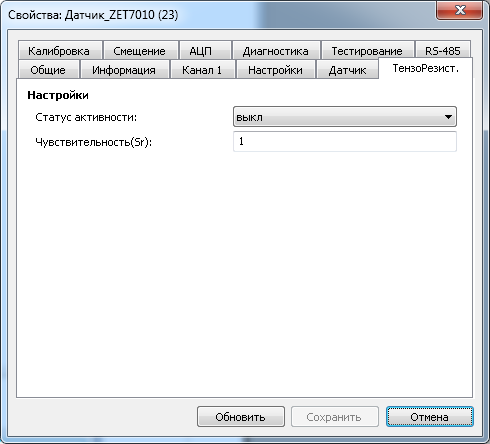

| Sensitivity threshold (minimal difference between sequentially measured values) | 0.0001 mV/V |

| Absolute measurement error (of the upper range limit) | 0.05 % |

| Relative measurement error (of the measured value) | 0.05 % |

| Additional measurement error (due to temperature measurement) | 0.05 %/10°C |

| Additional measurement error (zero time drift) | 0.05 %/10 min |

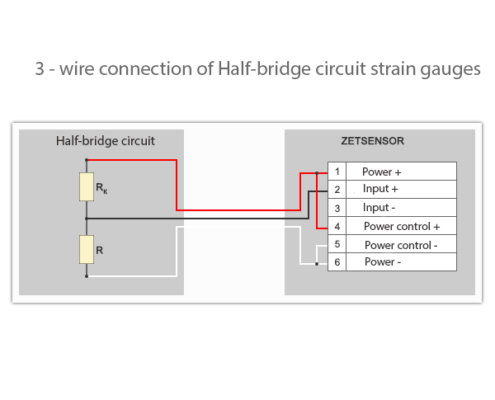

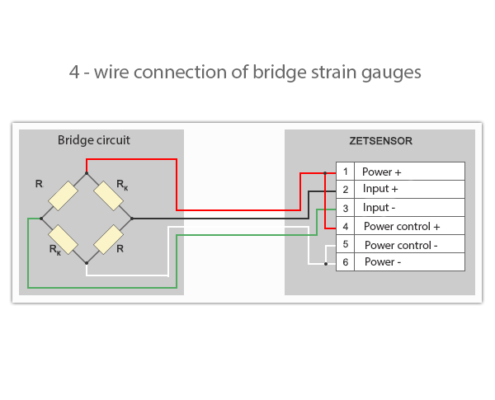

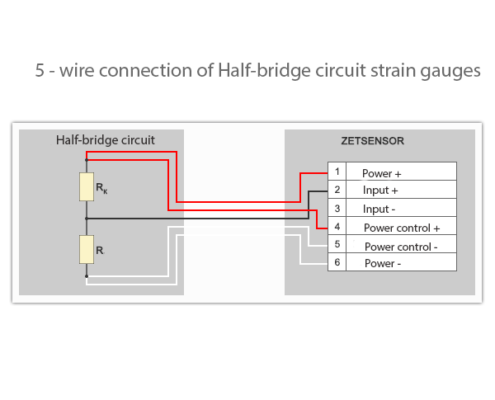

| Parameters diagnostics | feed control, data quality control, bridge or half-bridge integrity control, measuring unit calibration |

| Technical Specifications | |

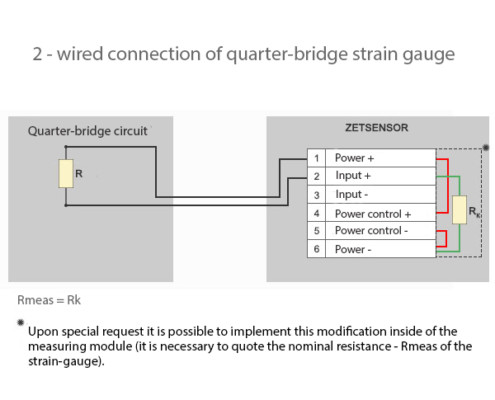

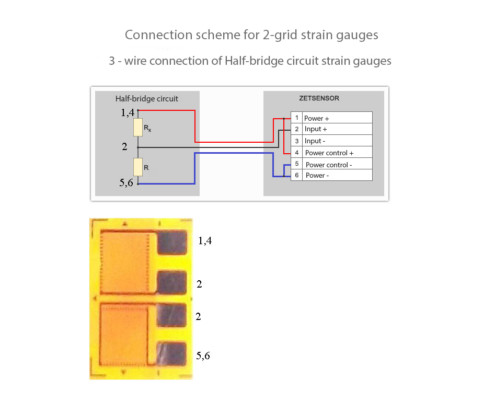

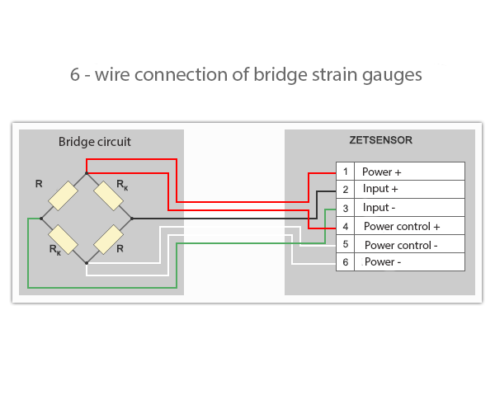

| Type of connected primary transducers (PT) | force gauge, bridge or half-bridge strain gauges (strain resistors) |

| Variable voltage fed to the PT | 3 ± 0.5 V |

| Frequency | 1250 ± 10 Hz |

| Maximal current fed to the PT | 10 ± 1.5 mA |

| Data refresh rate | 50, 250, 625, 1,250 Hz |

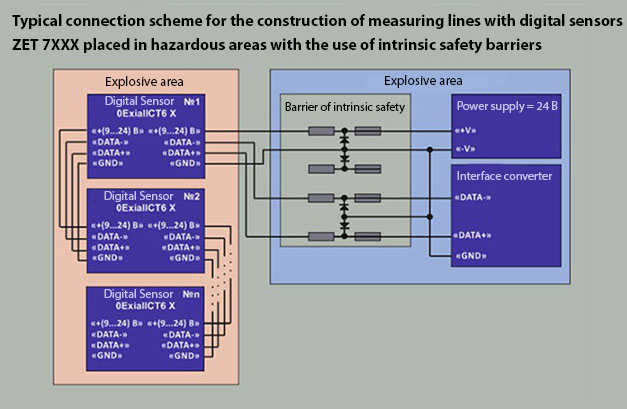

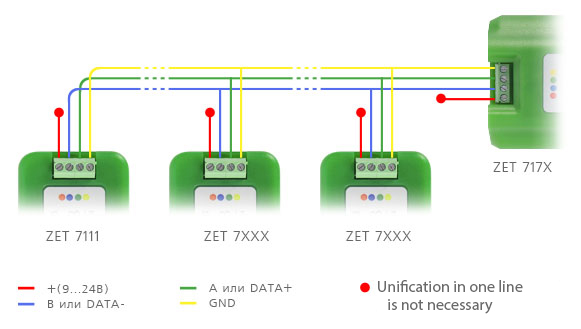

| Data interface | CAN 2.0 |

| Transmission rate | 100, 300, 1000 kbps |

| Performance Specifications | |

| Dimensions | 71×39×17 mm |

| Weight (kg) | 30 gr |

| Power supply | 9 to 24 V |

| Consumed power (w/o PT) | 0.5 W |

| Reverse polarity protection | Yes |

| Operational temperature range | -40 to +100 °C |

| Electromagnetic Compatibility | |

| IEC 61000-4-2, ESD | contact 4 kV, air 8 kV |

| IEC 61000-4-4, EFT | power supply 0.5 kV, signal 0.25 kV |

| IEC 61000-4-5, Surge | 500 V |