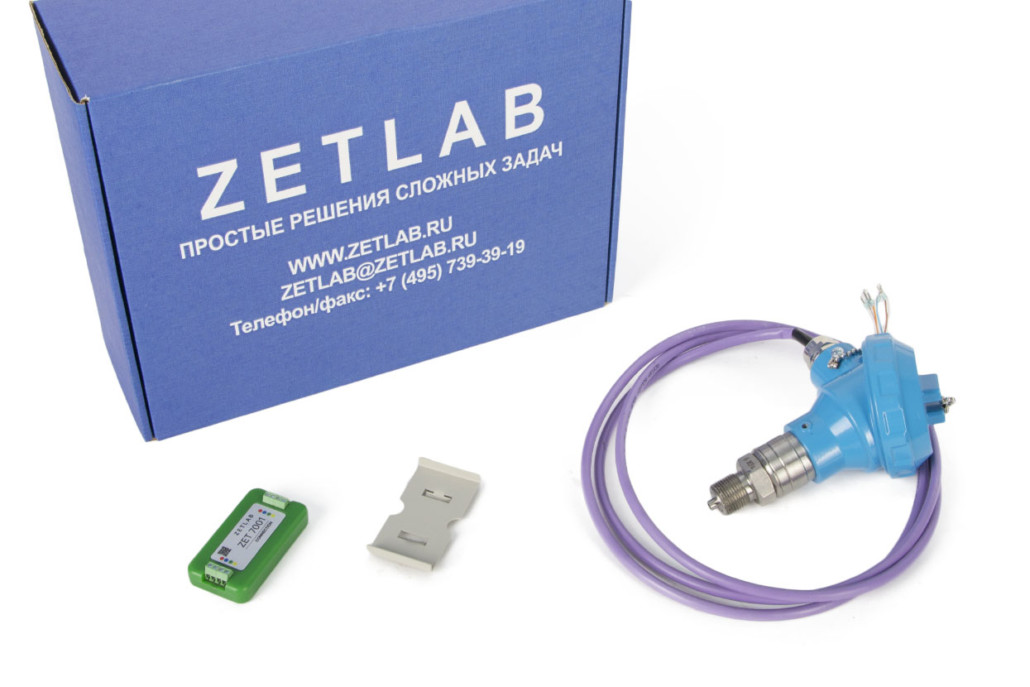

Digital gauge pressure ZET 7012-I-VER.1

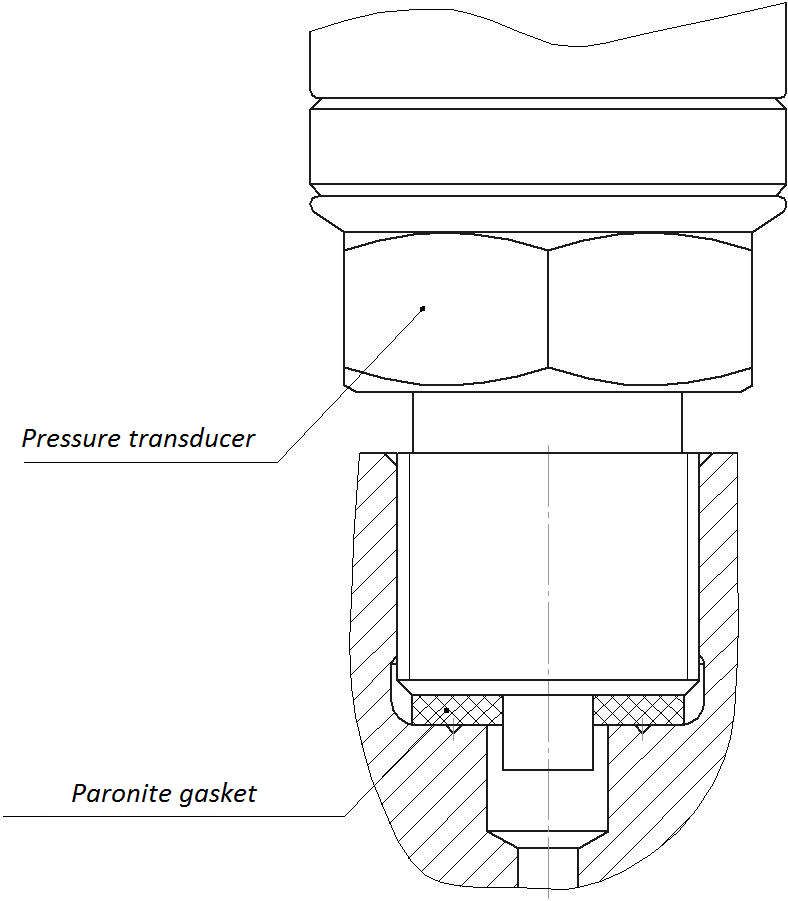

- Integrated primary transducer

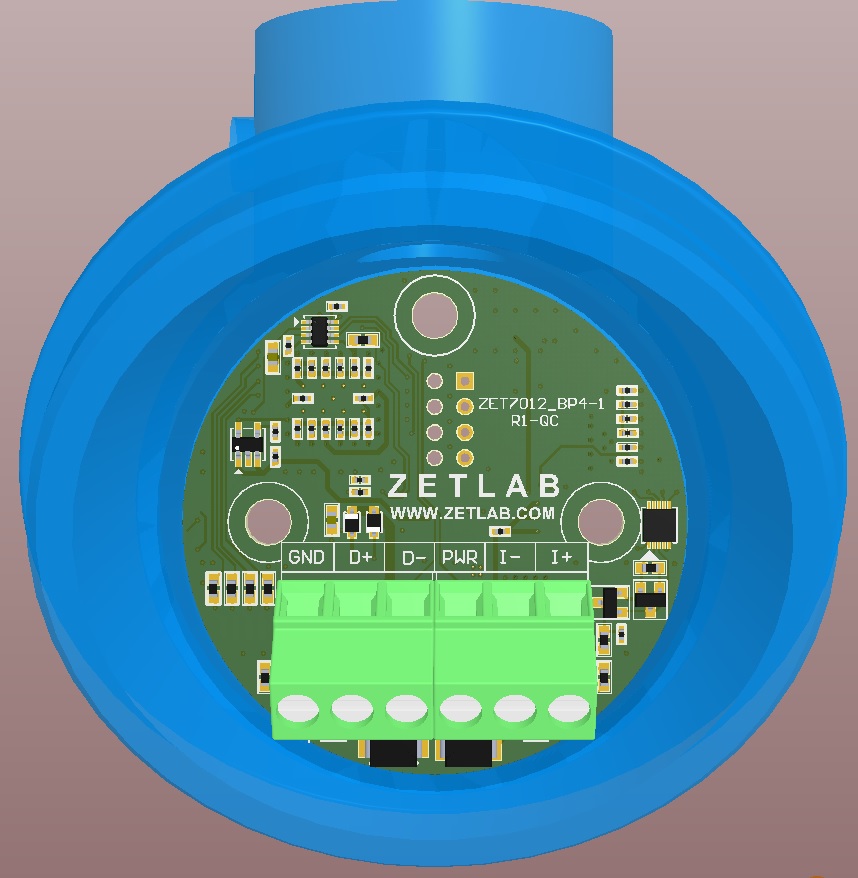

- RS-485 digital output

- 4-20 mA output version available

POR (price on request)

* Minimum order value: from 7 700 USD

Upper measurement range is to be specified in comments to the order

*Delivery term: from 3 weeks

Specifications

of ZET 7012-I-VER.1 digital gauge pressure

| Metrological specifications | ||

|---|---|---|

| Measured value | overpressure | |

| Measurement error (from measurement range) | 0,1% | 0,2% |

| Upper limit of pressure measurement range | 0,1 MPa; 0,16 MPa; 0,25 MPa; 0,4 MPa; 0,6 MPa; 1 MPa; 1,6 MPa; 2,5 MPa; 4 MPa; 6 MPa; 10 MPa; 16 MPa; 25 MPa; 40 MPa; 60 MPa; 80 MPa; 100 MPa; 160 MPa | |

| Resolution | 0,005 % | |

| Additional measurement error (caused by temperature change) | 0,1 %/10°C | |

| Technical specifications | ||

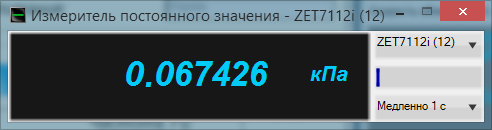

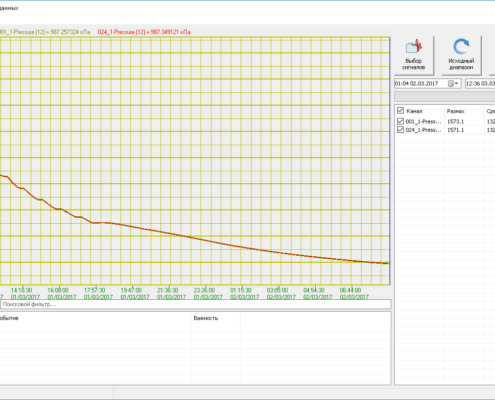

| Data refresh rate | 1 Hz | |

| Digital interface | ||

| Data transfer interface | RS-485 | |

| Exchange speed | 4800, 9600, 14400, 19200, 38400, 57600, 115200 bps | |

| Parity control | 0 – no control; 1 – control (parity, ODD) | |

| Exchange protocol | Modbus RTU | |

| Analog interface* | ||

| Current signal | 4-20 mA | |

| Load resistance | 0…250 Ohm | |

| Operational specifications | ||

| Power supply | from 9 to 24 V | |

| Consumed power | 0,5 W | |

| Reverse polarity protection | yes | |

| Operational temperature range | from -40 to +100 °C | |

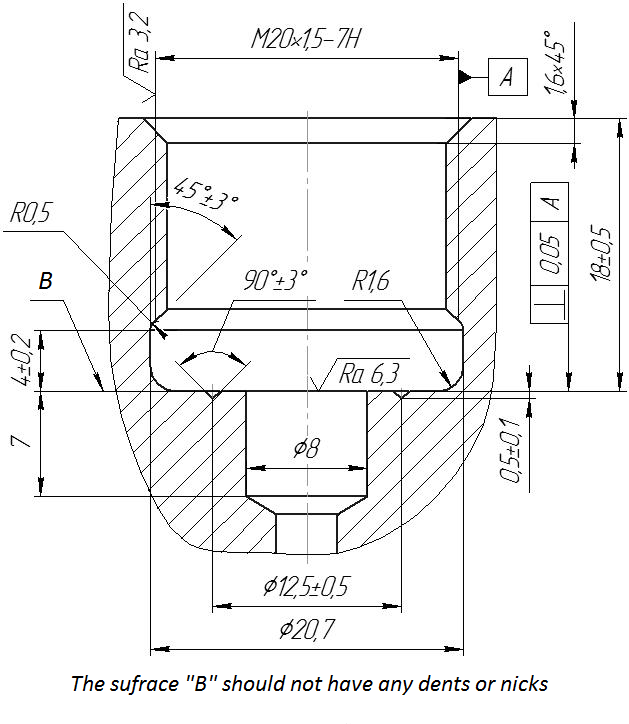

| Operation environment | liquids and gases non-aggressive to titanium alloys and stainless steels | |

| Design versions | Standard (IP63 protection degree) | |

| Pressure overload | 1,5×Upper limit of pressure measuring range | |

| Electromagnetic compatibility EMC | ||

| IEC 61000-4-2, ESD | contact 4 kV; air 8 kV | |

| IEC 61000-4-4, EFT | power supply 0,5 kV; signal 0,25 kV | |

| IEC 61000-4-5, Surge | 500 V | |

*Option