Counting Wheel Sets

Measurement of dynamic stress-strain state of structures

A system of diagnostics and condition monitoring of the building structures is designed for identifying the objects with strained bearing structures or tilt arising from external loads, temperature fields, and other factors.

Using the methods and means of strain gauging on structure elements, the research allows to determine the strain reasons, develop design solutions, analyze the impact of different factors on the strength of structures, etc.

Centralized Strain Gauge Measuring System

- Strain gauge sensors (sensors of force, resistive strain sensors, etc.).

- ZET 017-T8 strain gauge module.

- Computer with ZETLAB TENZO software.

Regular (analog) strain gauge sensors are often used as sensing elements of measuring systems, for example, to measure the weight of a rail car, control the tread area of wheel sets, count the cars of a passing train, etc.

Let us consider the centralized measuring system in terms of methods for counting cars of the passing train. Method of determining the number of train cars is based on the counting of wheel sets that passed through the measuring section.

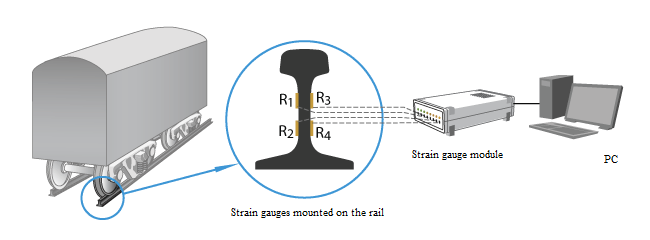

The measuring section comprises four resistive strain sensors attached to the rail as shown in the figure. For more accurate results, the same type of strain gauge sensors with identical specifications must be used.

A wheel set of the car passing the measuring section applies some force to the rails, which is recorded by the installed analog strain gauge sensors that transform it into electric signals.

The signals from strain gauge sensors are digitized by ZET 017-T8 strain gauge module. The module’s built-in strain gauge amplifier allows to connect the strain gauge sensors without using the intermediate amplifiers. Up to eight strain gauge sensors can be connected to a single strain gauge module.

The strain gauge module digitizes the signals received from the analog strain gauge sensors and transmits them to the computer with installed ZETLAB TENZO software. The digital signals are then processed by virtual tools and ZETLAB programs on the computer, which allows to eventually determine the number of cars of the passed train.

The data exchange between the computer and the strain gauge module is performed via USB 2.0, Ethernet, or Wi-Fi. The power is supplied from 220V → 12V power unit included in the supply package or from the external 12V battery, and may also be supplied via Ethernet line.

ZETLAB TENZO software supplied with the strain gauge module allows to:

- Receive and transmit the signals through the network.

- Process the signals coming from strain gauge sensors.

- Visualize and record the processed signals.

- Measure all kinds of electric parameters.

- Carry out static, modal, and sequence analysis, wavelet transformation, STA/LTA conversion, analysis of nonlinear distortion.

- Perform arithmetic, mathematic, logic operations and data filtering.

- Review error reports, convert data, and listen to the channels.

- Configure the ADC/DAC parameters, IP addresses of strain gauge modules, edit the database of sensors.