Diagnostics of gear units

Based on inter-correlation characteristics

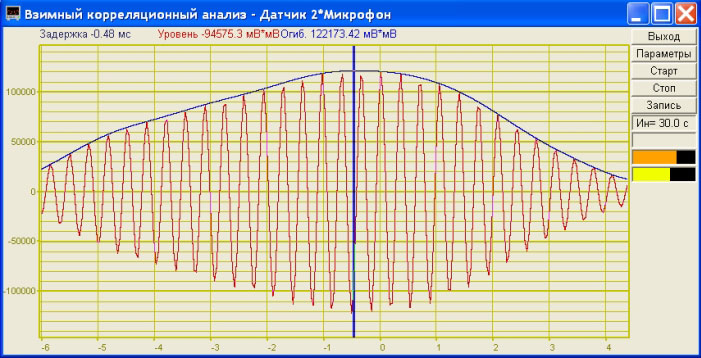

During the tests, it is important to install the vibration pickups so that they could perceive a signal of tested area.The microphone located near the tested area can be used to control installation of the sensors. By applying the inter-correlation method, it is possible to localize the main sources of noise and vibration signals. A velocity of longitudinal and transverse vibrations propagation in the metal is several kilometers per second. The velocity of acoustic vibrations propagation in the air is equal to 300 m/s. In these circumstances, it can be assumed that the signal from the source comes to the vibration pickup instantly and to the microphone with some delay. The inter-correlation function of signals from the vibration pickup and microphone allows measuring a time delay between the signals. If the delay in acoustic signal propagation from the tested area to the microphone corresponds to the location of correlation peak, it means that the main signal comes from the tested area and the vibration pickup is installed properly.

The figure shows the inter-correlation function calculated within the frequency band near the gear frequency of 3 kHz. Distance from the microphone to the tested unit is 0.5 m. The correlation peak is also at the mark point of 0.5 m.

See also:

- diagnostics of gear units;

- diagnostics of gear units based on spectrum of vibration signal;

- diagnostics of gear units based on super narrow-band spectrum;

- diagnostics of gear units based on co-spectrum characteristics;

- diagnostics of gear units based on spectrum of envelope curve;

- diagnostics of gear units based on order normalization.