Bearings Diagnostics

How long will the bearing last as compared to time it has been in operation already? When did the first defect appear? What is the source of damage? Is it change in bearing clearance, lack of lubrication or excessive vibration that causes the damage? The diagnostic system will provide the answers to these questions and many others.

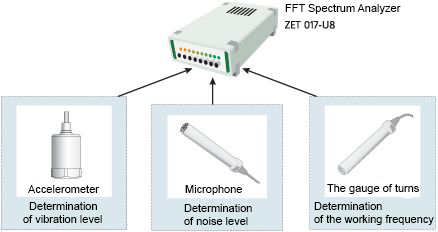

ZET 017-U8 spectrum analyzer, connected to vibration detectors, microphones and speed sensors, is used in the bearings diagnostics. Custom designed software allows you to evaluate the following parameters:

- overall level of vibration (integral value);

- peak value of vibration — micro-cracks in bearings cause occurrence of impact shock, which is accompanied by an increase in peak signal values of the vibration sensor;

- integral level of vibration in frequency range from 10 to 1,000 Hz;

- ratio of integral levels in low-frequency (LF) and high frequency (HF) fields — this parameter indicates the event of malfunction that is connected with high-frequency noise. This problem may arise due to lack of lubrication, defects of the rolling elements or separators;

- level of vibration on rotational frequency — beats on power frequency in case of the rotor imbalance;

- level of vibration on the subharmonic frequency — vibration on the fundamental frequency of separator rotation;

- overall level of harmonics — defects of balls, rollers, separators;

- vibration of the rolling elements.

Spectral analysis takes place in real-time, spectrum of the vibration sensor signal is shown on the monitor screen, all spectral components of the harmonics are distinguished by different colors.

All parameters are continuously monitored, measured and compared with normalized data. Operator is given a corresponding message in case they exceed the set standards of any parameter.

The system allows bearings and nodes acceptance testing performing.