Cavitation theory. Collier’s Encyclopedia.

Cavitation theory.

Cavitation— is the formation of vapour cavities in a liquid.The term “Cavitation” was first introduced by British scientist R.E. Froude. In the case if liquid pressure becomes equal to that of saturated vapour, it leads to vapour evaporation and vapor cavity (“bubble”) formation. In this case as an example we can consider water boiling process. As the water is heated, saturated vapour pressure increases. When the boiling temperature is reached, vapour pressure becomes equal to that of the environment, which leads to formation of vapour cavities. Vapour cavities are easily formed in the liquid under low pressure. As the environment pressure value exceeds that of the liquid saturated vapour, cavitation cavity collapses. It results into noise leading to vibration, which damages nearby structures, thus negatively influencing mechanisms performance. Local liquid pressure decline is caused by rapid relative motion of object and liquid.

Cavitation theory: Bernoulli’s principle

As Bernoulli’s principle says, energy of liquid withon tension impact is constant along the flow line. This is shown by equation:

p0+½ρυ02=p1+½ρυ12=p2+½ρυ22=const,

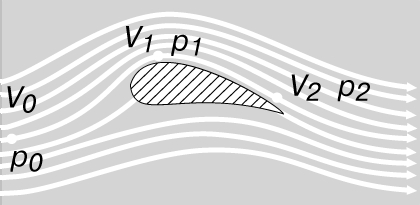

where p — pressure, ρ — density, and υ — speed. Indexes 0, 1 and 2 correspond to any three points of the flow line. From the equation it follows that speed increase leads to local pressure decline (proportinal to squared speed value). Any liquid particle moving along flow curve, for instance, in the profile flow (see Figure 1), accelerates and undergoes decrease of local pressure. If the pressure falls to the level of saturated vapour pressure, cavitaion is formed. This is the principle of cavitation formation on submerged wings, ship propellers, turbine and pump blades.

Figure 1. Profile flow: three points along the flow line. At the upper flow line point the speed value has highest value and the pressure – the lowest value.

In the case if the liquid is flowing inside of a pipeline, then, according to the mass conservation law (continuity equation), liquid speed is increasing at the pipeline chocking point, where cavitation is also possible.

Cavitation theory: Cavitation ratio

Cavitation process is the identical for a flow moving around static body and the environment of the body motion. In both cases the key parameters are relative speed and absolute pressure value. The relation between speed and pressure values causing cavitation is represented by dimensionless criteria σ, also called cavitation factor, and further specified by the equation:

σ=(p0-pυ)/(½p1+½ρυ02),

where ρυ — is the liquid saturated vapour pressure under given temperature value.

Cavitation theory: Cavitation types

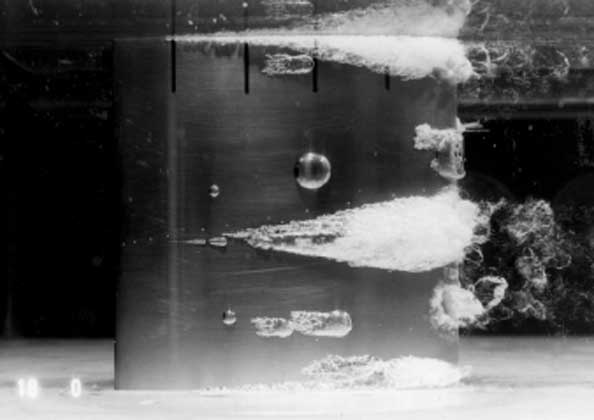

Figure 2 shows cavitation process on a stationary submerged wing (the picture was taken inside of hydrodynamic tunnel). At a certain flow speed value local pressure value close to the wing surface decreases to the level of water vapour pressure. This leads to cavitation cavities formation on the submerged wing surface. The cavities increase and shift along flow direction. (Since the cavities are formed outside of the wing surface, they have hemispherical shape). This cavitation type is called non-stationary (transient) cavitation. In the case if the submerged wing surface has any ridges, the cavities will be concentrating on it.

Figure 2. Cavitation on submerged wing surface. Transient and stationary cavitation on the wing surface inside of high-speed hydrodynamic tunnel.

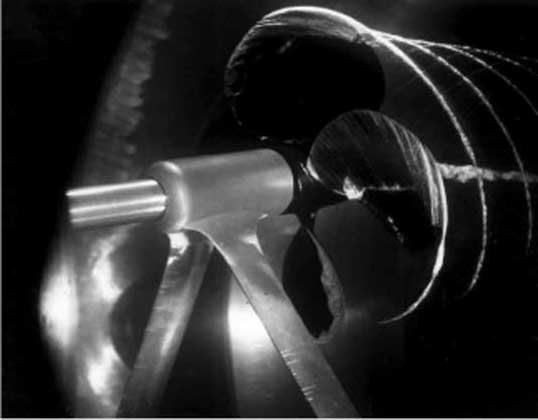

Cavitation may also occur around vortexes that are formed in high displacement and low pressure areas. Vortex cavitation can often be seen at the front ridge of the submerged wings, turbine blades and behind of propeller wheel hub. Simultaneous formation of several cavitation types is also possible. Figure 3 shows ship propeller with vortex cavitation at the front ridge of the blades, stationary and cavity cavitation at the blades surface and adjacent vortex cavitation behind of the wheel hub. Cavitation in liquid environment caused by sound wave is called acoustic cavitation.

Figure 3. Propeller cavitation: Ship propeller cavitation: vortex cavitation at the front ridge of the blades (right), vortex cavitation behind of the wheel hub (left), cavity cavitation at the blade (center).

Cavitation theory: Cavitation and machinery

Flow speed tends to decrease at the rear edge of the profile, where pressure value exceeds that of vapour pressure. Absence of cavitation forming parameters causes the cavities to collapse. Cavities collapse is accompanied by considerable energy release.

Cavitation theory: erosion

Large amount of energy dissipated during cavities collapse may lead to damage of submerged structures, ship propellers, turbines, pumps and nuclear facilities parts. Scale of such process as hydraulic erosion (also referred to as “scour”) may be different – from minor surface erosion after several years of operation to fault of complex structures.

Cavitation theory: vibration

Ship propellers cavitation may lead to periodic pressure fluctuations, affecting ship hull and power units. Cavitational vibration also negatively affects comfort of passengers and crew.

Cavitation theory: Efficiency factor and speed

Cavitation may considerably increase hydrodynamic resistance, thus leading to a decrease of efficiency factor of hydraulic machinery. Excessive cavitation level may limit thrust and speed of a ship. Cavitation factor may also be a reason of turbine or pump efficiency decrease or even failure.

Cavitation theory: Noise

Some part of energy which is dissipated in the course of cavities collapse is transformed into sound waves. This noise is especially adverse in the case of military ships, since it increases the possibility of being detected. Cavitation factor is also undesirable in the case of marine and turbopumps machinery. However, sometimes cavitation factor is created intentionally (for instance, in the case of hydraulic giant). The energy which is dissipated in the course of cavities collapse is used in water flow drilling of rock and for surface processing.

Cavitation theory: Biological impact

In the case of ultrasonic examination cavities formation and growth inside of bio-tissues is possible. Intense ultrasonic impact may lead to tissues damage.

References cited:

Collier’s Encyclopedia

Robert T. Knapp, James W. Daily, Frederick G. Hammitt, Cavitation, 1974

Victor A. Akulichev, Acoustic cavitation in cryogenic and boiling liquids, 1978

Levkovsky Y. L., Structure of cavitating flows, 1978

Ivanov, A.N., Hydrodynamics of Fully Cavitating Flows, 1980