Cavitation process forming: necessary conditions

Cavitation process is a process of vapour cavities formation with their further collapse accompanied by local release of considerable energy amount.

The time span between cavity or “bubble” formation to its collapse is several ms. At the moment of collapse the pressure inside of the cavity reaches 1000 atm at the temperature over 4000 K. All this energy is moving along a thin flow towards a small area at which the cavity has been formed. This results in material destruction at this area. In addition to that, the cavitation process is causing another phenomena:

- burst wave, damaging mechanical structures and their performance and causing noise;

- light emission (sonoluminescence);

- fission of water and dissolved materials into free radicals.

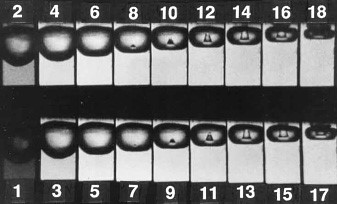

Figure 1. Cavitational bubble dynamics

Cavitation process – possible processes causing cavitation:

1. In most cases we witness cavitation process when we boil something – as the boiling process starts, one can see bubbles near the heated surface. These bubbles burst prior to reaching the surface, and that is the cavitation process.

2. In shipping industry the cavitation process negatively affects the lifetime of ship propellers and submerged wings. Cavitational voids are formed on the propeller blades and submerged wings ridges due to pressure swing. Collapsing voids may withdraw metal pieces from the surface. It leads to formation of cracks, friction and turbulence increase. After some time it eventually results in propeller or wing fault. Similar process may be observed in centrifugal pumps, ESC hydraulic turbines.

Figure 2. Cavitation on ship propeller

3. Cavitation process may also have positive effects. For instance, cavitation process in ultrasound bath along with the impact of active cleaning media results in active surface cleaning of various parts, coins, jewellery, PCB-s, etc from hard deposits.

4. Cavitation process is also used for medical purposes – for renal gravel (lithotripsy), body fat (liposuction) and dental calculi removal.

In order to detect cavitation, it is necessary to understand the cavitation process. Cavitational bubble collapse causes a wide emission spectrum, including acoustic waves. Thus, it is possible to detect cavitation only by using a sensor, capable of detecting acoustic waves. However, all the processes that may be accompanied by cavitation, are followed by ambient sounds: generator and propeller noise, friction noises, etc. These sounds mainly belong to low-frequency range below 100 kHz, and that is exactly why in the course of cavitation sensor design it is necessary to exclude low-frequency noise, which may jam the useful signal. Resonance or wide-band sensors with operating range over 100 kHz perfectly suit for such tasks.