Acoustic emission transducers

Resonance acoustic emission transducers key element is a piezoelectric cell (crystal) converting mechanical displacement into electrical signal.

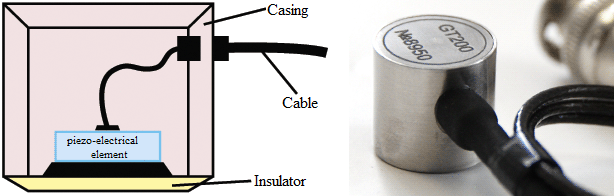

Piezoelectric cell is placed inside of special package with a bottom plate and connection plug. Standard structure of acoustic emission transducers is shown in the figure below:

Acoustic emission transducers: standard structure

The sensor is exposed to strain wave impact, affecting its bottom part. The strain waves are then converted into electrical signals. These signals are received by a preamplifier, and then, at the final stage of signal recording, are forwarded to measuring and processing instruments. For the purpose of easy installation and decrease of electromagnetic blasts, the preamplifier can be placed inside of tansducer package.

One of the key requirements to acoustic emission transducers is a high sensitivity level. Transducers having plain frequency response are supposed to be high-quality sensors. However, in most cases, it is the resonance sensors that have the highest sensitivity level, besides, they are less expensive then the broad-band sensors. These acoustic emission transducers have relatively narrow frequency band, in which the prevailing oscillations take place. The frequency band width is normally determined by piezoelectric cell dimensions and shape. Sensor’s frequency range tends to prevail in the course of acoustic emission signal shape and spectrum forming. Operating frequency range can be controlled by means of selecting resonance acoustic emission transducers having required frequency characteristics. Frequency range adjustment s an important feature allowing to set the instrument to the necessary frequency range as well as to increase the SNR. In practi,ce most of the measurements are performed by means of acoustic emission sensors with the frequency value of 150 kHz.