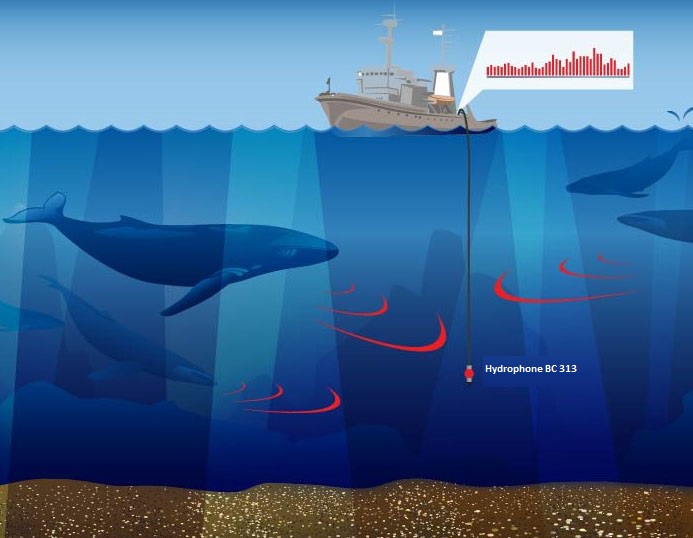

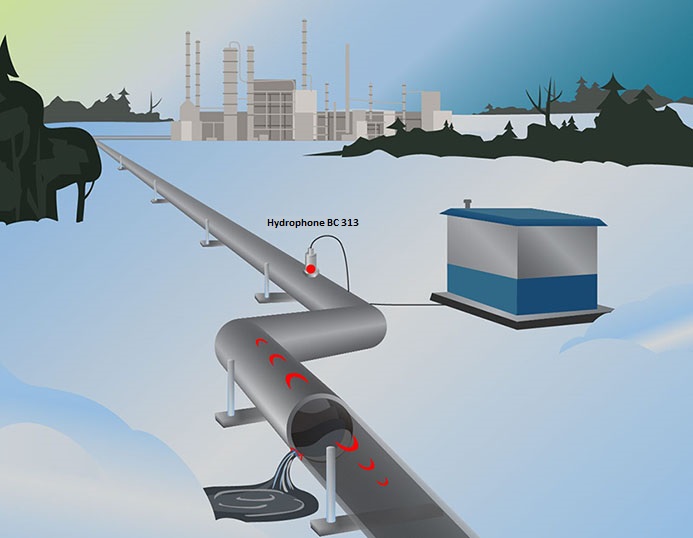

Nowadays application sphere of hydroacoustic research encompasses military use as well as the civil applications:

- marine navigation safety control;

- fishery and marine mammals industry;

- mareographic research – seabed mapping;

- exploration activities at ocean shelve;

- localization of industrial noise sources, etc.

Let us consider the last item in more details.

Recently the use of complex recorders using vector-phase methods has become increasingly popular for the purposes of noise sources localization in hydroacostic field. The research of acoustic fields characteristics is based on methods of simultaneous recording of pressure field and pressure field gradient with the use of sound pressure transducers and vector transducers (oscillatory acceleration transducers, accelerometers, or seismoacoustic transducers) located at particular areas of the pressure field.

These methods are based on such basic notions as energy directional flux and velocity, energy density at a particular point of the environment, localization of energy flux (these notions have been thoroughly researched by theoretical physicist N. A. Umov, who has applied them to elastic body energy). In 1884 the notion of directional energy flux was introduced by J. Poynting, who used a directional vector notion in the description of energy propagation (this vector is commonly known as “Poynting vector”).

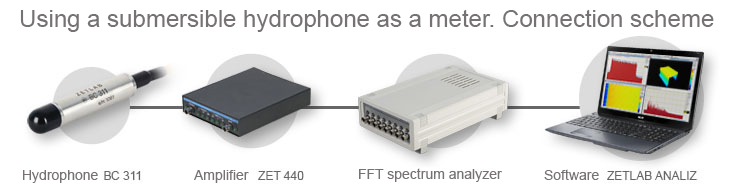

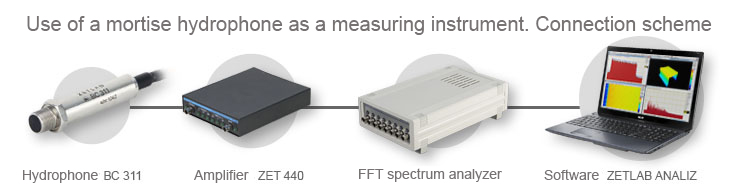

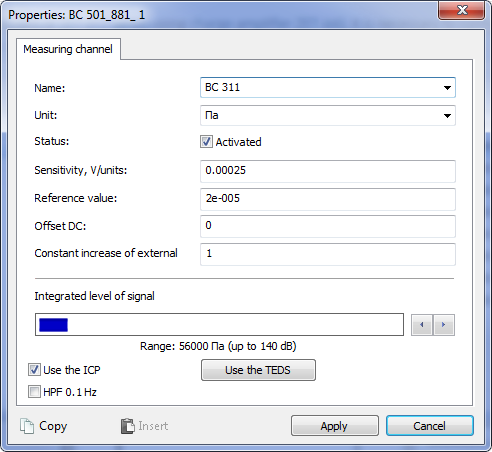

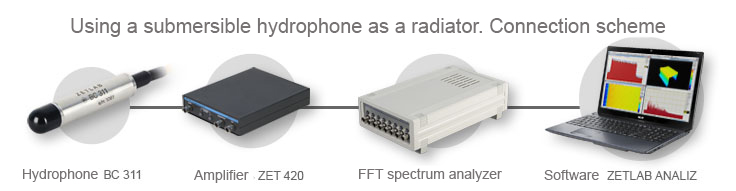

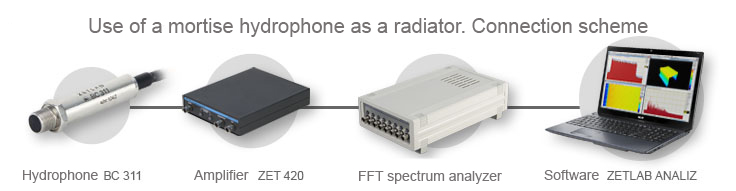

The structure of a combined hydroacoustic recorder is generally represented by a leak-proof sphere (its dimensions are negligibly small if compared to the wavelength). The sphere incorporates primary transducers: two hydrophones with external sensing elements used for pressure conversion (in this example – BC 311) and a triaxial vector seismograph used for recording of pressure gradient, oscillating velocity, etc. (in our case – seismograph BC 1313).